“Then you set your blade height at 7/8 in. wide strips (depending on your rafter spacing),” he writes.

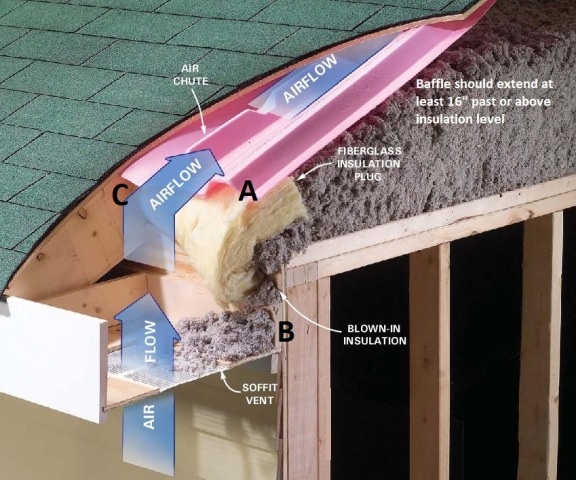

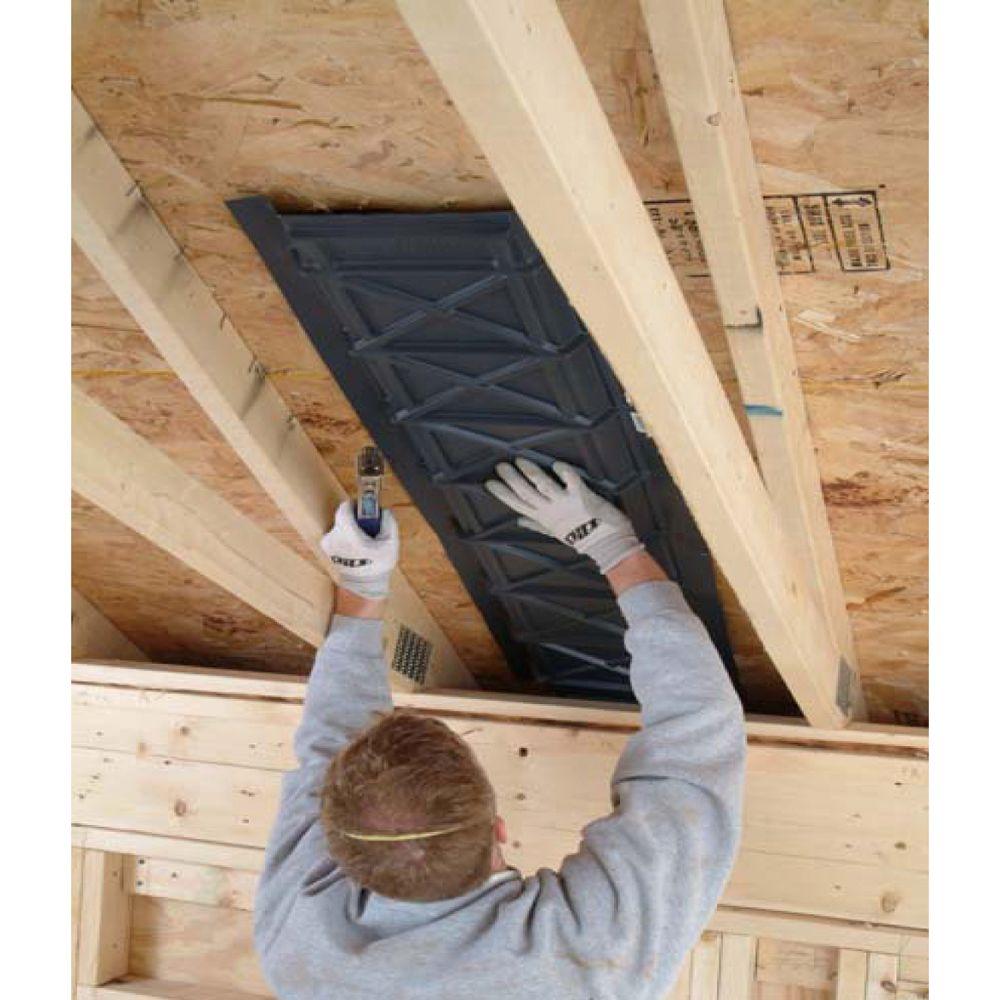

“You use a tablesaw to rip a sheet in 16-in. PaulCP adds that the assembly will leak “unless you tape the paper well at the seams, and caulk or foam where the lath and rafters meet.”Īn alternative, PaulCP says, would be to use sheets of rigid foam insulation, cut scored on a tablesaw so it could be bent to form a chute. Unroll the paper over it and staple it down to each of the lath pieces every 6 in. Now, cut the centers between the lath pieces that are side by side. You will be left with a piece of paper with two lath strips that you can attach to the sides of the rafters.” “Each center will have a lath border on both sides. “Tape down to a clean concrete floor every 16 in. If he’s determined to use it, PaulCP suggests starting with bundles of lath 3/4 in. PaulCP replies that while housewrap is cheap (and assuming it works as an air barrier), there’s still a lot of labor involved in bwkwood’s plan. In fact, he adds, builders who are aiming for tight houses are giving up on housewrap as an air barrier, even when all seams are taped. If he staples Tyvek into his rafter bays, he’ll be the first guy I heard of who ever did it. “There are rolled and liquid applied materials that would also serve, but they’re not under discussion here. “Air barrier is generally a rigid material…drywall, plywood, rigid foam, etc.” says davidmeiland. “Housewrap is most definitely an air barrier,” DanH replies. “Housewrap is not an air barrier material and will give you virtually zero benefit if installed as you describe it,” davidmeiland tells bwkwood. He hopes the housewrap works as an air barrier to reduce air infiltration (and unwanted moisture) into roof cavities while maintaining the performance of the insulation.īut would housewrap accomplish what bwkwood hopes? Opinions are divided. The gap immediately below the sheathing would allow air to travel from soffit vents to a ridge vent, carrying away any moisture that worked its way up through the insulation. vent chute between sheathing and house wrap? It needs to be simple, time effective and cost effective.”īwkwood’s quest for economy and performance is the subject of this month’s Breaktime Spotlight. “Does anyone out there have a nifty idea on how I could maintain a 1 1/2-in. “This would certainly fill the role as an air barrier in my rafter bays,” bwkwood says. wide and fit them into the rafter bays in place of commercially available baffles. His plan is to cut the housewrap into strips 16 in. “It is going to drive me crazy to spend another $200 for the plastic insulation baffles at Home Depot.” “The R19 kraft faced fiberglass for the ceilings and walls (1000 sf) cost me only $200,” bwkwood writes in a post at the Breaktime Construction Techniques forum. He’s rounded up some bargain insulation and is now looking for a cheaper alternative to insulation baffles for a cathedral ceiling. He’s in the process of putting up an addition with as little cash outlay as possible. A bargain-hunting builder searches for an alternative to commercially available insulation baffles for use in a cathedral ceilingīuilding on a tight budget? That’s a situation many of us have faced, and bwkwood is one of them.

0 kommentar(er)

0 kommentar(er)